- -10%

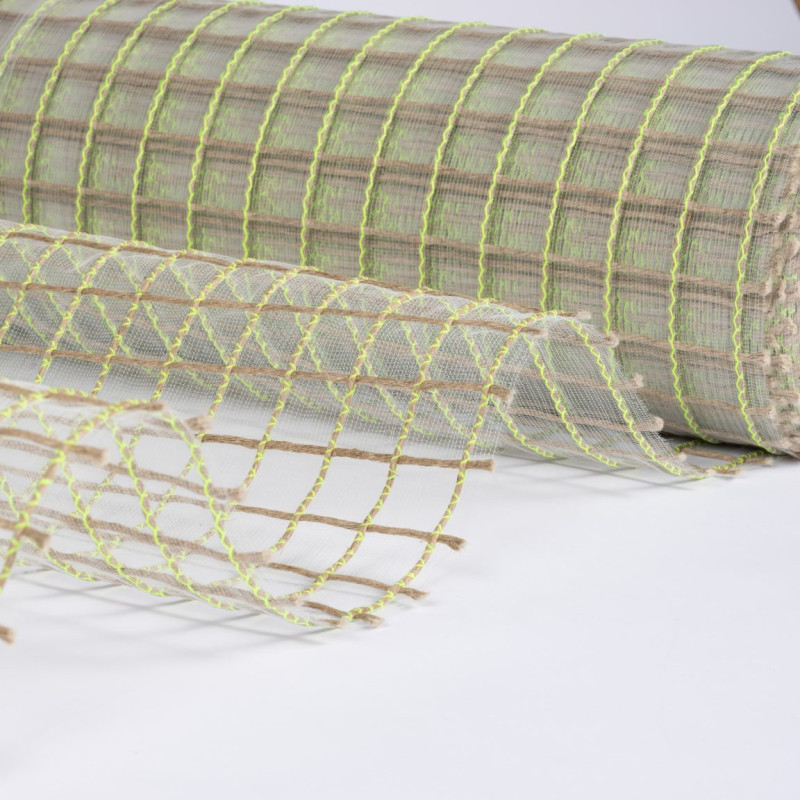

powerRibs™ 235g Mesh (1100mm)

- Write a review

(zł126.00 za 1mb)

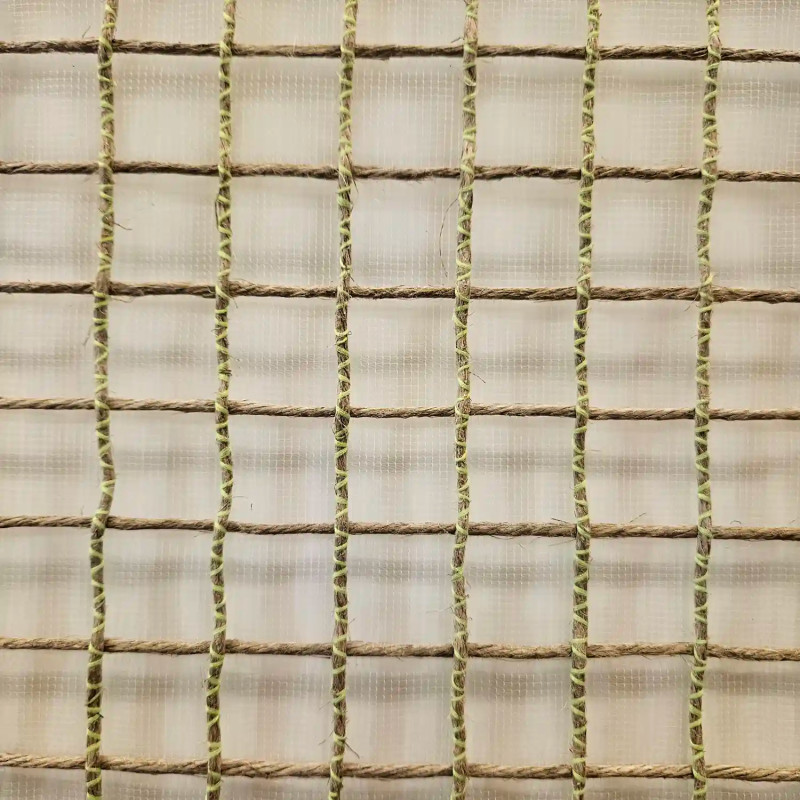

PowerRibs™ is a fabric in the form of ribs made from natural (flax) fibers, designed to significantly increase bending stiffness in thin-walled composites.

PowerRibs creates a structure resembling ribbing, which imitates the venation of a leaf for applications requiring high structural performance. When combined with natural ampliTex™ fibers, it is possible to achieve the same bending stiffness and weight as a monolithic carbon fiber laminate.

The fabric has a width of 1100 mm and is sold by the linear meter.

Delivery terms

Delivery terms

§ 6 DELIVERY

Return of goods

Return of goods

§ 9 RIGHT OF WITHDRAWAL

Name: Bcomp LTD.

Adress: Passage du Cardinal 1, CH-1700 Fribourg

Country: Szwajcaria

Contact: [email protected]

ExaTec Composites sp. z o.o. is official distributor of Bcomp Ltd. materials.