- -10%

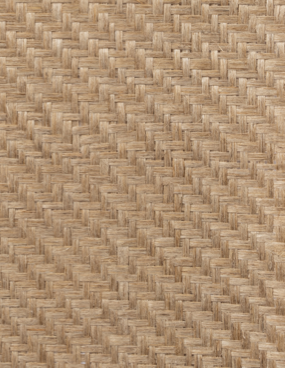

ampliTex™ 200g Twill 2×2 (1000mm)

- Write a review

zł82.85

zł74.56

Save 10%

(zł74.46 za 1mb)

ampliTex 200g Twill by Bcomp is a linen fabric with a twill weave and a weight of 200 g/m².

In addition to the ecological benefits, natural fibers also offer an attractive, natural appearance and excellent vibration damping properties.

The material is suitable for most lamination processes, such as:

- Hand lay-up (laminating),

- Vacuum bagging,

- Resin infusion,

- RTM,

- Autoclave,

- Press molding.

The fabric has a width of 1000 mm and is sold by the linear meter.

Delivery terms

Delivery terms

§ 6 DELIVERY

Return of goods

Return of goods

§ 9 RIGHT OF WITHDRAWAL

Name: Bcomp LTD.

Adress: Passage du Cardinal 1, CH-1700 Fribourg

Country: Szwajcaria

Contact: [email protected]

ExaTec Composites sp. z o.o. is official distributor of Bcomp Ltd. materials.